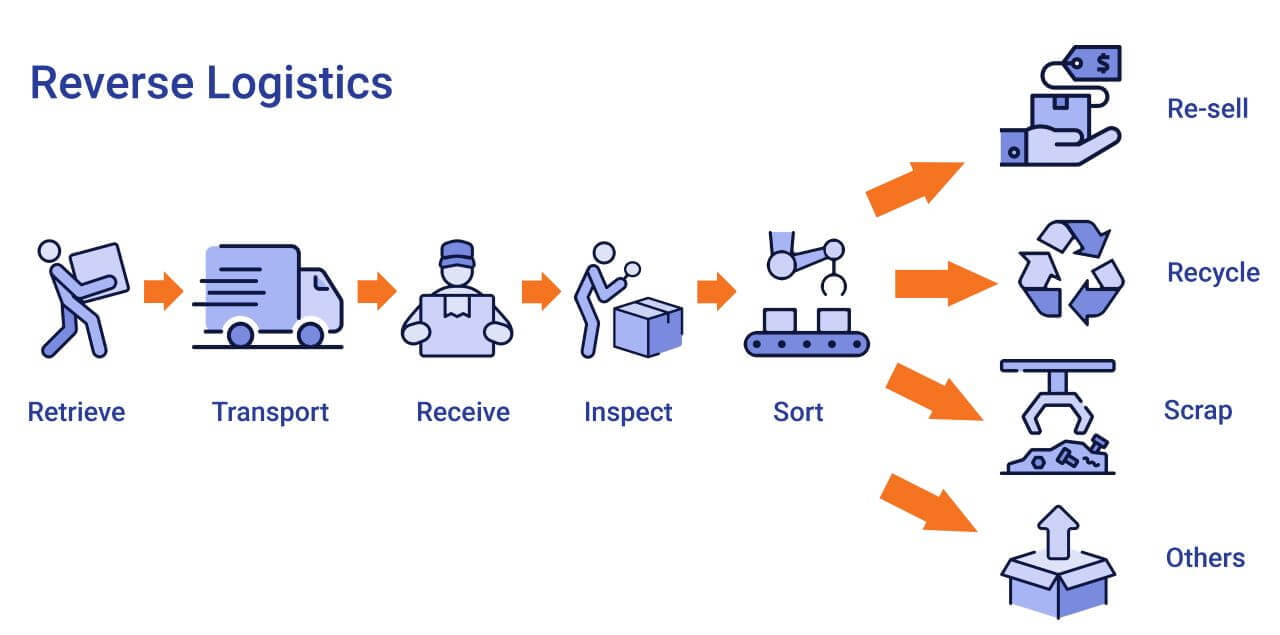

Reverse logistics refers to the process of managing the flow of products in the opposite direction of the traditional supply chain. It involves handling product returns, recycling, repairs, and the overall management of the reverse flow of goods. In today’s business landscape, effective reverse logistics has become increasingly important as it not only impacts customer satisfaction but also contributes to sustainability efforts and cost optimization.

According to industry research, return rates for online purchases can be as high as 30%, creating a significant challenge for companies to handle these returns efficiently. By implementing robust reverse logistics processes, companies can streamline the return process, minimize costs, and enhance customer satisfaction. Let’s explore the key aspects of reverse logistics and why businesses need to prioritize their management.

Product Returns Management:

Managing product returns efficiently is crucial for maintaining customer satisfaction and loyalty. An effective reverse logistics system streamlines the return process, ensuring a seamless experience for customers. This includes providing clear return policies, easy-to-use return channels, and timely refunds or replacements.

Recycling and Waste Management:

Reverse logistics plays a critical role in managing the recycling and disposal of products that have reached the end of their lifecycle. By implementing proper recycling and waste management practices, businesses can reduce their environmental footprint and comply with regulatory requirements.

Repair and Refurbishment:

Reverse logistics also involves handling products that require repair or refurbishment. This includes assessing the condition of returned items, identifying opportunities for repair or refurbishment, and reintroducing them back into the market. By extending the product lifecycle through repairs, businesses can reduce costs and minimize waste.

Inventory Management:

Efficient reverse logistics enables businesses to optimize inventory management. By accurately tracking returned products, businesses can determine the condition of the items, identify potential resale opportunities, and make informed decisions regarding inventory levels, stock replenishment, and order fulfilment.

Cost Optimization:

Reverse logistics can significantly impact a company’s bottom line. By effectively managing product returns, repairs, and recycling, businesses can minimize costs associated with customer dissatisfaction, excess inventory, and waste disposal. Optimizing reverse logistics processes can lead to improved profitability and operational efficiency.

Customer Satisfaction and Retention:

Providing a positive post-purchase experience is crucial for customer satisfaction and retention. By implementing a well-structured reverse logistics system, businesses can handle product returns promptly, address customer concerns efficiently, and ensure a smooth and hassle-free experience. This, in turn, fosters customer loyalty and enhances the reputation of the business.

Regulatory Compliance:

Reverse logistics involves compliance with various regulations related to product returns, recycling, and waste management. Businesses must stay updated with local, national, and international regulations to ensure proper handling, disposal, and recycling of products. Adhering to regulatory requirements not only avoids legal consequences but also demonstrates a commitment to social and environmental responsibility.

Sustainability and Corporate Social Responsibility:

Effective reverse logistics align with sustainability and corporate social responsibility (CSR) initiatives. By implementing environmentally-friendly practices, such as recycling, reusing, and reducing waste, businesses contribute to a more sustainable future. This resonates with environmentally conscious consumers and strengthens the company’s CSR image.

Collaboration and Partnerships:

Managing reverse logistics often requires collaboration with various stakeholders, including suppliers, logistics providers, recycling facilities, and repair centres. Building strong partnerships with these entities is essential for seamless reverse flow management, effective communication, and timely execution.

Continuous Improvement:

Reverse logistics is a dynamic process that requires continuous evaluation and improvement. Businesses should analyze the performance of their reverse logistics operations, identify areas for enhancement, and implement strategies to optimize efficiency, reduce costs, and enhance customer satisfaction.

In conclusion, managing reverse logistics is essential for businesses to effectively handle product returns, recycling, and the reverse flow of goods. By prioritizing this aspect of the supply chain, companies can enhance customer satisfaction, reduce costs, comply with regulations, and contribute to sustainability efforts. A well-managed reverse logistics system ensures efficient handling of returns, maximizes value recovery, and minimizes environmental impact.

Contact us today to learn more about our global sourcing services and how we can contribute to your business growth. Follow our LinkedIn page for more content on supply chain and logistics.