In an increasingly complex and interconnected global market, supply chain management is more critical than ever. To meet evolving demands, businesses are turning to innovative technologies, and one such solution gaining traction is the Supply Chain Digital Twin.

The Digital Twin is a virtual representation of a physical supply chain, complete with real-time data integration, analytics, and simulation capabilities. It allows businesses to visualize, analyze, and optimize their supply chain operations, providing valuable insights for decision-making and enhancing overall performance.

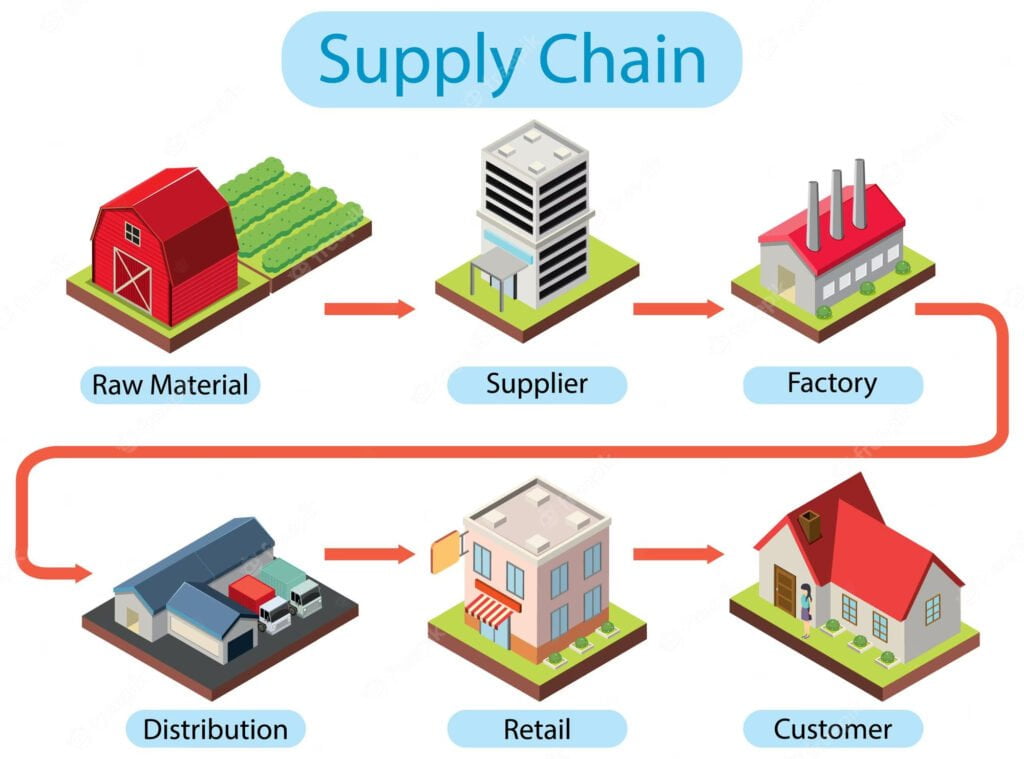

At its core, the Supply Chain Digital Twin mirrors the end-to-end processes of the physical supply chain, capturing the interplay between suppliers, manufacturers, distributors, and customers. By integrating data from various sources, including Internet of Things (IoT) devices, sensors, and ERP systems, the Digital Twin creates a dynamic and accurate reflection of the supply chain in real-time.

Key Benefits:

1. Enhanced Visibility: The Digital Twin provides unparalleled visibility into every aspect of the supply chain, identifying bottlenecks, inefficiencies, and potential disruptions. This level of visibility enables businesses to take proactive measures to mitigate risks and optimize performance.

2. Real-Time Data and Analytics: With continuous data streaming, Digital Twin offers real-time analytics, allowing businesses to monitor key performance indicators (KPIs) and track progress against predefined targets. This data-driven approach empowers supply chain professionals to make informed decisions promptly.

3. Scenario Analysis and Simulation: The Digital Twin’s simulation capabilities enable businesses to model different scenarios, evaluate the impact of potential changes, and test new strategies in a risk-free environment. This empowers supply chain managers to anticipate outcomes and optimize strategies accordingly.

4. Resilience and Adaptability: In an era of supply chain disruptions caused by natural disasters, geopolitical tensions, or unexpected events, the Digital Twin equips businesses with the tools to build resilient supply chains. By identifying vulnerabilities and creating contingency plans, companies can respond effectively to unforeseen challenges.

5. Collaboration and Data Sharing: The Digital Twin facilitates seamless collaboration among supply chain partners by sharing real-time data and insights. This transparency fosters trust and enables stakeholders to work together to optimize the entire supply chain ecosystem.

6. Efficiency and Cost Savings: Optimizing supply chain processes through the Digital Twin leads to improved efficiency and reduced costs. By streamlining operations, businesses can optimize inventory levels, minimize lead times, and enhance overall productivity.

Conclusion:

In an ever-evolving and unpredictable global market, the Supply Chain Digital Twin has emerged as a powerful tool for businesses seeking to enhance resilience, visibility, and efficiency. By embracing this cutting-edge technology, companies can navigate the complexities of the supply chain landscape, make data-driven decisions, and create agile and responsive operations.

As supply chain challenges continue to evolve, the Digital Twin remains a key enabler of success, providing the insights and capabilities needed to build a future-ready supply chain that can withstand disruptions and deliver superior value to customers. With the Supply Chain Digital Twin, businesses can reimagine supply chain management and usher in a new era of efficiency and adaptability.

Contact us today to learn more about our global sourcing services and how we can contribute to your business growth. Follow our LinkedIn page for more content on supply chain and logistics.